General Product Information

Reproductions?

There will be many

pictures of original antique weapons and items on this web site. The pictures of original items are

for

identification purposes only. We do not sell original parts,

only reproductions of original parts to be used in the building of a

reproduction or restoration of an original antique. From time to time we

will have some original pieces for sale. As we get our web site finished

we will be listing them in a new section designated just for original items.

Until then you may contact us about any original parts or pieces you may be

looking for. The picture to the right is a comparison of an original item

(left side of picture) to

the casting (right side of picture) we reproduced it from. Notice the casting in

the picture still has the casting gate on the bottom. We ship all parts as cast with

the casting gates still on them unless it is an assembled lock or finished item.

If you have any questions about the condition of a product it will be in when shipped please fell

free to call.

There will be many

pictures of original antique weapons and items on this web site. The pictures of original items are

for

identification purposes only. We do not sell original parts,

only reproductions of original parts to be used in the building of a

reproduction or restoration of an original antique. From time to time we

will have some original pieces for sale. As we get our web site finished

we will be listing them in a new section designated just for original items.

Until then you may contact us about any original parts or pieces you may be

looking for. The picture to the right is a comparison of an original item

(left side of picture) to

the casting (right side of picture) we reproduced it from. Notice the casting in

the picture still has the casting gate on the bottom. We ship all parts as cast with

the casting gates still on them unless it is an assembled lock or finished item.

If you have any questions about the condition of a product it will be in when shipped please fell

free to call.

Estimated Delivery Times?

There are many castings, screws, barrels, stocks and ramrods which we keep in stock. These items can usually ship out quickly. However there are items that are made as they are ordered, these usually include stocks, ramrods, assembled locks, assembled ready to shoot weapons and some barrels.

In the investment casting process there are sometimes delays for parts that are not in stock, so due to this process we require patience from our customers. The average estimated delivery time on our parts is usually 90 - 120 days if the parts you order are not in stock. I will explain a little on how the process goes. The picture below shows the brass side plate casting on the left, and the wax on the left which it originally started as.

First the waxes have to be made which we do in our shop usually takes a couple of weeks to get a batch of waxes ready. Second we take these waxes to the foundry which usually take 8 - 10 weeks for these to be transformed in to a casting and returned to us. Once we receive the castings from our foundry, they are sorted and then cleaned which usually takes another week. Finally they will be pulled for each order and shipped out.

Sometimes the castings do not turn out for a number of reasons. When this happens, the process starts all over again from square one with making the waxes. The whole process usually takes 12 - 14 weeks. This is why sometimes there are longer than expected delivery times, when parts have to be rerun. We assure you that the quality of our parts are well worth any wait, as most of the parts we offer never have and probably never will be offered by anyone else.

Assembled Lock?

To

the left

is a picture of an assembled lock for our Series 554 Doglock. Our

assembled locks come with hardened internals, hardened and tempered

springs and a hardened frizzen. We also polish and fire blue the

screws. We hand tune each lock we assembled to make sure it is putting

out the maximum amount of spark and speed. When ordering an assembled

lock set you will only need to polish the outside of the lock and drill

and tap it for side lock screws. Notice the frizzen and dog catch are

colored due to the case hardening they have received.

To

the left

is a picture of an assembled lock for our Series 554 Doglock. Our

assembled locks come with hardened internals, hardened and tempered

springs and a hardened frizzen. We also polish and fire blue the

screws. We hand tune each lock we assembled to make sure it is putting

out the maximum amount of spark and speed. When ordering an assembled

lock set you will only need to polish the outside of the lock and drill

and tap it for side lock screws. Notice the frizzen and dog catch are

colored due to the case hardening they have received.

Set of Lock Castings?

To the right is a picture of a set of lock

castings. When ordering a set of lock castings you will need to cut off

castings gates, straighten the lock plate if needed, drill and tap holes

for assembly, harden the frizzen and harden and temper the springs. The

set of lock castings do not come with any screws. If you need screws

please request a lock screw set for the same series number of lock you

are ordering. Most lock screw sets cost $24.95 and include all screws

necessary for assembling the set of lock castings.

To the right is a picture of a set of lock

castings. When ordering a set of lock castings you will need to cut off

castings gates, straighten the lock plate if needed, drill and tap holes

for assembly, harden the frizzen and harden and temper the springs. The

set of lock castings do not come with any screws. If you need screws

please request a lock screw set for the same series number of lock you

are ordering. Most lock screw sets cost $24.95 and include all screws

necessary for assembling the set of lock castings.

Screws?

The screws we offer are

manufactured in Standard American Threads or are unthreaded blanks, we do not offer

screws in original threads as there are no taps available for these original threads. If you

have any questions about the thread size of any screw in our catalog please

give us a call for details on our thread sizes. See a few examples of

screws to the left.

The screws we offer are

manufactured in Standard American Threads or are unthreaded blanks, we do not offer

screws in original threads as there are no taps available for these original threads. If you

have any questions about the thread size of any screw in our catalog please

give us a call for details on our thread sizes. See a few examples of

screws to the left.

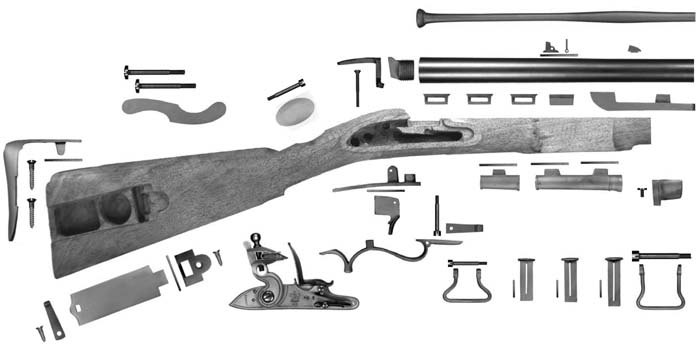

The Rifle Shoppe Parts Set?

When you order a Parts Set from the Rifle

Shoppe, you can rest assured that each part is duplicated from the original

weapon down to the smallest detail. The quality and authenticity of our

weapons are most important to us, so we research each weapon and compare it

with others if possible to make sure we do not miss any details. Our parts

sets include the lock (as a set of lock castings with lock screw set or as

an assembled lock, which is hardened, tempered and ready to install), stock,

barrel, furniture and ramrod as well as all of the correct screws and pins

needed for assembly. The screws and pins included in our parts sets are the

correct size and shape needed for assembly. We try to duplicate the correct

screw heads, but manufacture our screws in standard American threads as

there are no taps available for original threads. The picture above shows a

714 parts set with assembled lock (714 PARTSAS), we have removed the casting

gates for the picture above but all our parts with the exception of

assembled items come with the casting gates still on them. Bayonets,

Cleaning Tools, Spanners, Yokes etc. are considered accessories and are

available at an additional cost. We currently do not offer instructions for

our parts sets, but we do offer a stock and parts drawing on a few of our

parts set that will aid you in the assembly process, if needed see pages

266-267 in our 2007-2008 catalog to see what drawings are offered. If you would like to receive a

parts listing of the items you will receive in a set please contact us and

request a parts listing for the set you are interested in.

We are currently working on a video for lock assembly and spring hardening

which will be available in the near future, if interested please call to

check on the availability.

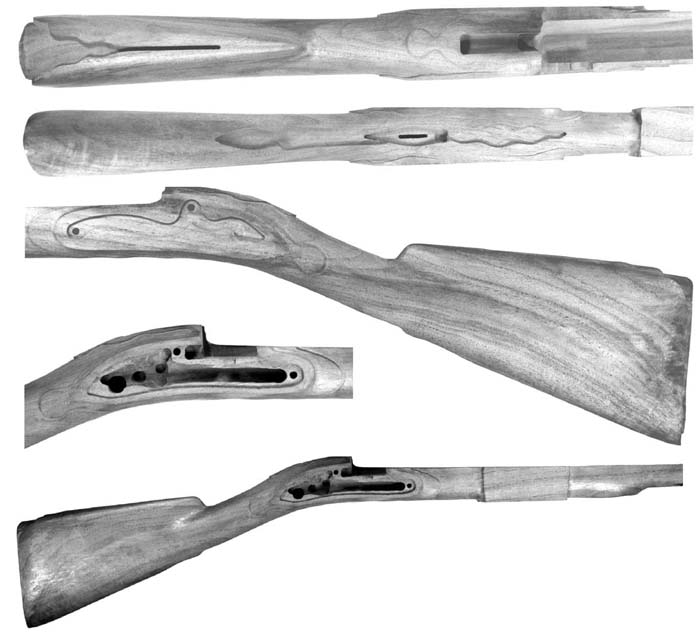

The Rifle Shoppe Stocks

Our stocks are pre-shaped and in-letted for most parts with the exception of very small parts like band springs and some of the fancy side plates and thumb pieces. They are cut to almost exact size leaving just enough for sanding. Forearms are pre-shaped and in-letted. We leave a small block of wood in the forend of long stocks to give you something to hold on to while working on it. Our stocks are made in standard plain American Walnut unless ordered differently. Below is a listing of the different optional/grades available from our supplier if you would like something in a fancier grade of Walnut. Call on availability of Presentation grade pieces.

Plain ~ No Figure, Straight Grain

Light Figure ~ Light Curly or Grain Color in 25% of stock.

Medium Figure ~ Curly or Patterned grain in 50% of Stock ( A nice stock but not

a bragger)

Heavy Figure ~ Over 75% Curly and or Patterned (A respectable stock to

everyone.)

Presentation ~ Very Rare Pieces - usually three separate patterns or colors.

(The Presentation grade is Gorgeous and fit for presentation to the best.)

American Walnut

- Light Figure $125.00 Extra

- Medium Figure $195.00 Extra

- Heavy Figure $500.00 Extra and UP

- Presentation $ CALL

Hardening and Tempering Notes

It has been my experience that the secret to

good flintlocks is in the polishing and hardening, especially on early locks

that do not have internal bridles. You can double the speed on an early lock

by hardening the cock, tumbler and lock plate you can also speed up later

locks by making sure the lock plates are hardened. We use 4140 steel on all

our lock parts except frizzens and springs which are 6150. These are oil

hardening steels, but we don't recommend oil hardening, but you will find

that if you case-harden the lock plate, internals, and frizzen then use a

water quench it will give you a finer finish and smoother bearing surface.

You are not adding anymore carbon by doing this, but you are keeping the

parts from losing any carbon while you are bringing the part up to the

correct heat range (1650° to 1675° or very bright reddish orange). You will

find this especially true with frizzens where carbon content is very

critical. A case-hardened and water quenched 6150 or 1095 steel frizzen will

spark 10 times better and hotter than an oil hardened one. Always be sure to

draw the tail of the frizzen to a deep blue color up into the edge of the

pan cover area.

To harden a spring we use a water quench. Use a propane torch to bring the spring slowly up to a very bright

red almost orange (1500°), making sure the spring is a consistent color all

over, then drop it into a container of room temperature water. Handle the

spring carefully, as it is now glass hard. Polish the spring. For tempering

the spring use an area where the light is not too bright so you can see the

color changes easily. Start heating the spring from the largest end first

going over the entire spring and the colors will start out a straw or gold

color going into a scarlet or purplish color, then into a shinny deep blue

color, continue heating slowly and this blue will disappear and start all

over with a clear shinny color, then back into the gold color, then the

scarlet or purplish color (approx. 700°), then into a dark blue black

(approx. 750°). As soon as you get the blue black color even lay the spring

down on a piece of wood an let it cool, when cooled it will be a perfect

spring. If you find that it does not have enough tension, re-harden and

re-temper to just as the blue black color appears, on smaller springs you

can stop at the purplish color (approx. 725°). I have re-hardened and

re-tempered some springs 8 or 9 times to get just the right feel. Always

polish the bearing surface on the foot of the spring. If you do not want to

try hardening your springs just return them after you fit and polish them

and we will harden and temper them for you.

On early locks without internal bridles try to get as close a fit on the

tumbler, lock plate and cock as possible with no binding. Be sure to harden

all three. These early type locks will last you almost forever if you take

time on these points in the beginning. When you are polishing use “wet or

dry” emery paper, go all the way to 600 or 800 grit before you ever use a

buffing wheel so as to keep everything square and true. Also a little more

polishing after hardening everything because the better the finish, the

faster the lock. As a rule of thumb polish every piece that moves or

something moves on.

Flints are also important in having an excellent lock. Use good flints that

are large enough. Early locks and military locks used larger flints then we

tend to put in them today. If your frizzen doesn't kick all the way open,

try using a larger flint instead of grinding on the camming surface, or put

your flint in bottom side up as some early locks were made to use spall type

flints which have no top or bottom. The shaped flints we have today did not

come into major use until after 1800. The British were still using chips and

spall type flints in the war of 1812.